The Drill Chuck Explained: A Complete Guide to Size, Keys, and Features

The drill chuck is the “business end” of every power drill—the critical component that holds the bit and puts the power to work. Yet for many new and even experienced DIYers, the markings, types, and features of a chuck can be a source of confusion. What does the size mean? Why do some need a key? What are those numbers on the collar for?

This expert guide will demystify the drill chuck completely. We’ll explain its fundamental purpose, break down the different types, clarify what all the numbers and specifications mean, and even touch on more advanced concepts. By the end, you’ll understand this essential tool component, enabling you to work more safely, effectively, and choose your next drill with confidence.

What is a Drill Chuck and What is its Purpose?

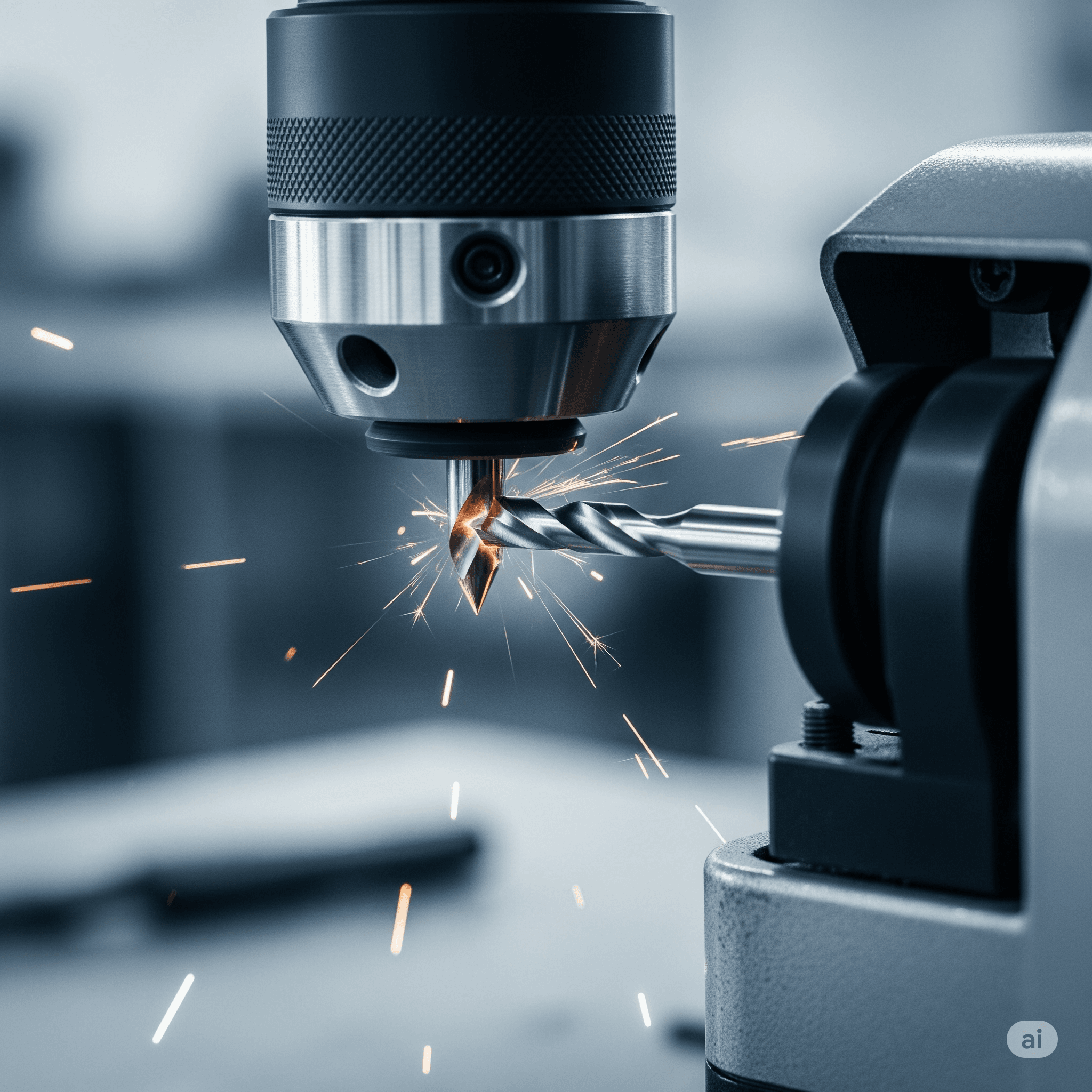

At its core, a **drill chuck is a specialized, self-centering three-jaw clamp** located at the end of a drill’s spindle. Its one and only purpose is to securely grip the shank (the smooth end) of a drill bit or other rotating accessory. It acts as the crucial link that transfers the rotational power from the drill’s motor to the tool bit, allowing you to drill holes or drive screws. Think of it as the drill’s “hand”—it needs to have a firm, precise, and reliable grip to do its job properly.

Keyed vs. Keyless: The Two Main Types of Chucks

Drill chucks primarily come in two varieties, defined by how they are tightened.

Keyed Chucks

A keyed chuck requires a special tool—the **drill chuck key**—to tighten and loosen its jaws. The key has a gear on its tip that engages with teeth on the body of the chuck. Turning the key provides significant mechanical advantage, allowing the user to apply immense clamping force on the drill bit.

- Pros: Superior gripping power, making them less likely to let a bit slip under heavy load or during the intense vibrations of a hammer drill. They are the standard for drill presses and heavy-duty corded drills.

- Cons: Bit changes are slower, and the chuck key is notoriously easy to lose.

Keyless Chucks

A keyless chuck is tightened and loosened by hand. The user simply grips the chuck’s outer sleeve and twists it to open or close the jaws. Most modern cordless drills feature a keyless chuck for its speed and convenience.

- Pros: Extremely fast and convenient bit changes. No key to lose.

- Cons: Can sometimes loosen during high-torque applications or when the drill’s rotation stops abruptly. They may not grip as tightly as a properly tightened keyed chuck.

Understanding Chuck Size and Capacity

This is one of the most important specifications when buying a drill. The **drill chuck size** or **capacity** refers to the **maximum diameter of a bit shank that the chuck’s jaws can accept.**

The two most common sizes for consumer and professional drills are:

- 3/8-inch (or 10mm): This is the standard size for most general-purpose homeowner drills. It’s perfectly adequate for drilling holes and driving screws in most common tasks. It can accept any bit with a shank diameter of 3/8-inch or less.

- 1/2-inch (or 13mm): This larger size is found on more powerful, heavy-duty, and professional-grade drills. A 1/2-inch chuck is necessary for larger bits used in demanding applications, such as large hole saws, auger bits for wood, or large masonry bits for concrete.

Key Takeaway: A 1/2-inch chuck can hold any bit a 3/8-inch chuck can, but a 3/8-inch chuck cannot hold bits with shanks larger than 3/8-inch. If you anticipate heavy-duty work, a drill with a 1/2-inch chuck is the more versatile choice.

Our Pick for Versatility: A 1/2-Inch Cordless Hammer Drill

For most users, a quality cordless drill with a 1/2-inch keyless chuck offers the best combination of power and versatility. The larger chuck capacity ensures you’ll never be limited, and the hammer function allows you to tackle light masonry projects.

Check Price on AmazonWhat Do The Numbers Mean? A Guide to Markings and Settings

This is a major point of confusion. There are numbers printed on the chuck itself, and then there is a rotating ring of numbers located *behind* the chuck. They serve two completely different purposes.

Numbers on the Chuck Itself: Capacity Markings

Any numbers stamped directly onto the metal body of the chuck relate to its technical specifications. You will typically see its capacity range, for example: **”1.5 – 13mm”** or **”1/16 – 1/2″**. This simply indicates the minimum and maximum shank diameter the jaws can hold.

Numbers Behind the Chuck: The Torque Clutch

The rotating ring with numbers (e.g., 1, 3, 5… 20) plus a small drill bit icon is the **adjustable torque clutch**. This is NOT part of the chuck’s gripping mechanism. Its purpose is to control the amount of rotational force (torque) the drill applies when driving a screw.

- Low Number (e.g., 5): This setting provides very little torque. The drill will “clutch out” (make a clicking sound and stop turning the screw) with minimal resistance. This is perfect for driving small screws into soft materials like drywall or pine, preventing you from stripping the screw head or driving it too deep.

- High Number (e.g., 20): This setting provides maximum torque for driving large screws into hard materials.

- Drill Icon Setting: Turning the collar to this symbol **bypasses the clutch entirely.** This delivers the motor’s full power and is the setting you must use for drilling holes.

A Deeper Look: What is Drill Chuck Runout?

For precision-focused users, “runout” is an important concept. In simple terms, **runout is a measure of how much a drill bit wobbles off-center as it rotates.** In a perfect world, a bit would spin with zero wobble (zero runout). In reality, tiny manufacturing imperfections in both the chuck and the drill’s spindle cause a minuscule amount of wobble. For 99% of tasks like hanging shelves or building a deck, this is completely unnoticeable and irrelevant. However, for high-precision metalworking or fine furniture making, excessive runout can lead to slightly oversized or oval-shaped holes.

Tip for Better Grip: Hex-Shank Drill Bits

A common frustration with keyless chucks is a round bit slipping under high torque. Hex-shank bits solve this problem. The flat sides of the hexagon give the chuck’s jaws a much more secure grip, preventing any slippage. They are an excellent upgrade for any keyless drill.

Check Price on AmazonConclusion: Mastering Your Drill’s Most Important Component

The drill chuck is more than just a simple clamp; it’s a precision component that dictates your drill’s capability and versatility. By understanding the difference between keyed and keyless chucks, the importance of 3/8″ vs. 1/2″ capacity, and the function of the torque clutch, you can get the absolute most out of your tool. This knowledge not only makes you a better DIYer but also empowers you to choose the perfect drill for your needs when it’s time for an upgrade.